This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Description

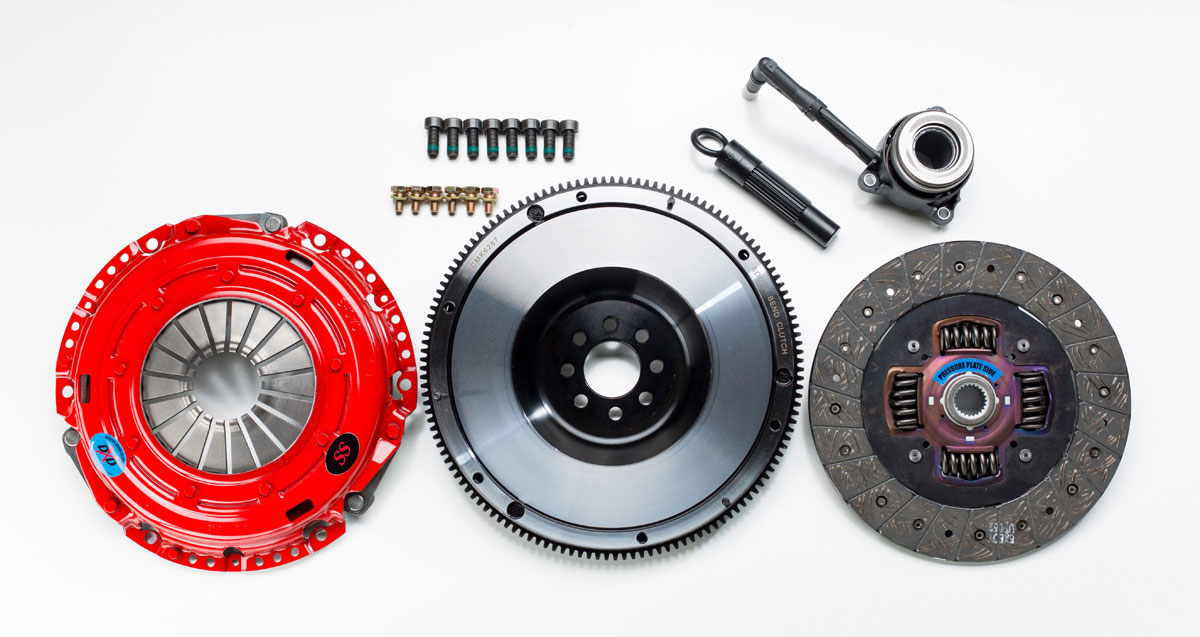

Drag racing requires a Single Mass Steel Flywheel to be included with each kit when the original design is Dual Mass Flywheel. This clutch package is built to handle heavily modified cars and designed to function according to the specific needs of the 1/4 and 1/8 mile track. The pressure plate for this kit is SFI approved Race Cover engineered to disengage with less pedal travel shortening the shift time. Discs are a puck design, which reduces rotational mass and is assembled with all high carbon component pieces for maximum strength. The friction material used is Graphite impregnated Ceramic perfectly suited for drag racing because of its maximum friction co-efficient, rapid heat dissipation and abrupt engagement characteristics.

Recommended uses are drag, pulling, drifting.

Torque Rating of 575 ft-lbs.

Race Engineered Pressure Plates (SS) used in Stage 3 and 4 clutch kits:

These performance clutches deliver more transmittable torque and stability, longer life and superior thermal resistance. They also deliver noticeably better dynamics through a higher clamp load when driving the vehicle to its limits.

Flywheel Features

Flywheels manufactured by SBC are made from low carbon, hot rolled steel that is highly resistant to warping and perfectly suited for the friction materials mated to them. Single mount CNC machining guarantees precise tolerances and perfect balance exceeding O.E. specifications. Extensive field testing has been done to determine the proper weight for each specific vehicle and to ensure smooth operation, safety and durability under extreme operating conditions.

Additional information

| Weight | 35 lbs |

|---|---|

| Dimensions | 20 × 18 × 6 in |

Model

Generation

| Make | Model | Year | Generation |

|---|---|---|---|

| Make | Model | Year | Generation |

| VW | GTI | 2006 - 2009 | MK5 |